Limonite properties and uses

Limonite properties and uses

Blog Article

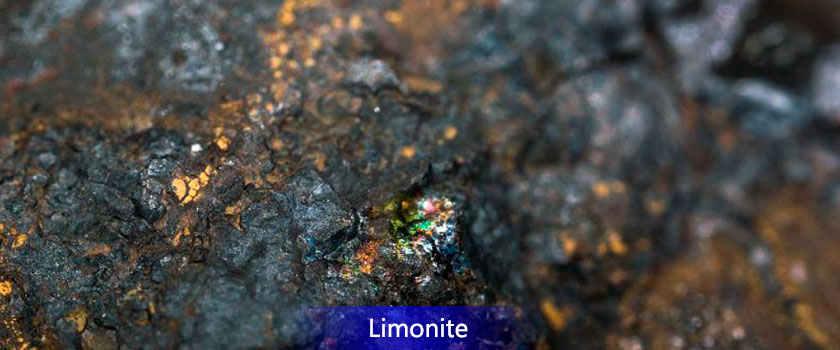

Limonite is a secondary iron ore with a high iron content, generally around 50%. The main component of limonite is iron oxide, which is generally brown and is a natural multi-mineral mixture. Usually, limonite is irregular, strip-shaped or earthy, and has a relatively soft texture.

The formation of limonite is relatively complex. Under the mutual sulfidation of acidic igneous rocks and limestones, the sulfide gradually turns into limonite, and then after a long oxidation, it evolves into the iron cap limonite deposit today.

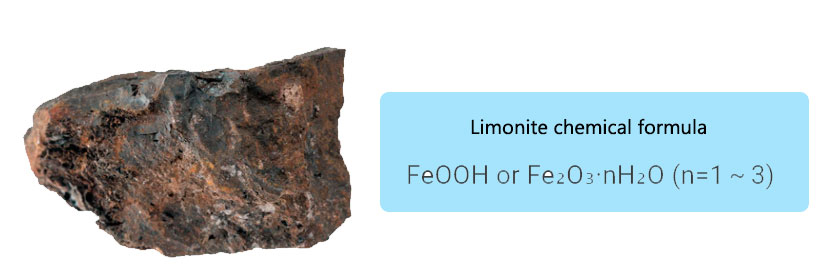

Limonite chemical formula

The answer is: FeOOH or Fe₂O₃·nH₂O (n=1~3)

From the chemical formula, we can see that limonite is mainly composed of iron and oxygen elements, and contains a certain amount of crystal water.

When the chemical formula of limonite is FeOOH, it means that the iron element mainly exists in the form of iron hydroxide.

When the chemical formula of limonite is Fe₂O₃·nH₂O, it indicates that the iron element mainly exists in the form of ferric oxide.

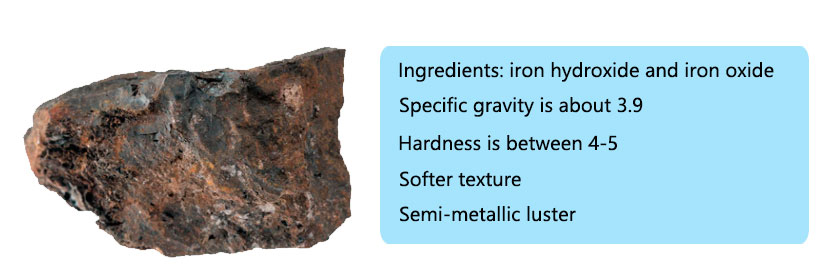

Limonite properties

The main factors affecting the properties of limonite are the water content and the amount of impurities. Limonite is an iron ore composed of iron oxides, the main components of which are iron hydroxide and iron oxide. Physically speaking, the specific gravity is about 3.9, the hardness is between 4-5, the texture is soft, and the semi-metallic luster is. Chemically speaking, because it contains iron hydroxide, it is easy to dissolve and react in an acidic environment to generate Fe3+ ions and water.

Application areas of limonite

Building materials field: Iron oxide in limonite is an auxiliary material for cement production, and its main function is to pyrolyze dicalcium silicate to increase the hardness and strength of cement.

Pigment field: Limonite can be used as an auxiliary material for coatings and paints, mainly providing two tones of khaki and brown.

Metallurgical field: Limonite has a relatively high iron content and is also a raw material for the production of alloy materials such as steel and cast iron.

Chemical industry: Iron hydroxide in limonite is a chemical product for making iron oxides and ferrites, such as catalysts in the production of chemical fibers and rubber.

Agricultural industry: Elements such as iron, magnesium, and calcium in limonite improve the quality of acidic soil by neutralizing acidity.

Environmental protection: Limonite wastewater treatment also plays an important role. It can be used as a filter medium to effectively remove heavy metal impurities such as lead and arsenic in wastewater.

Limonite beneficiation process

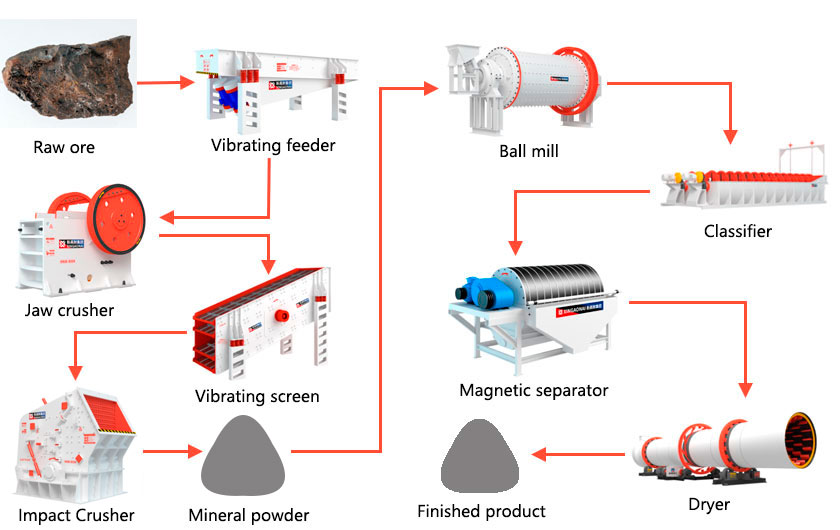

Main equipment: vibrating feeder, jaw crusher, impact crusher, vibrating screen, ball mill, classifier, magnetic separator, dryer, etc.

Specific process: The limonite raw material is evenly fed into the jaw crusher by the vibrating feeder for the first crushing, and then the impact crusher is used for medium and fine shaping and crushing, and then screened by the vibrating screen. The materials that do not meet the requirements are sent back to the impact crusher, and the qualified materials are sent to the ball mill for grinding. After grinding, the limonite material is sent to the spiral classifier, and the mixture in the material is cleaned and graded according to the principle of different sedimentation speeds. The washed and impurity-free materials pass through a magnetic separator to separate the magnetic substances in the materials, and finally pass through a dryer to dry and dehydrate them to produce finished products.

Author:[Xingaonai] Report this page